Tuesday, 11 June 2013

Monday, 10 June 2013

Types of Denison pumps repaired

Types of Denison pumps repaired:

| 3DO2 | 3DO3 | 3DO6 | 4DO1 | A3D10 | A3DO3 | A3DO6 | BBT-O7O7 |

| M11H | M11V | M14G | M14H | M14V | M1C | M1D | M1F07 |

| M2F07 | M46 | M46H | M46V | M4C | M4D | M4E | M6G |

| M6H | M6V | M7G | M7H | M7V | MF07YQ | MFO7 | MFO8 |

| MFO9 | P05 | P07 | P080 | P09 | P11 | P110 | P11P |

| P11S | P11V | P12 | P14 | P140 | P14P | P14S | P14V |

| P16 | P16 | P1FO7 | P1V07 | P200 | P24 | P24P | P24S |

| P260 | P2F07 | P30S | P3F07 | P3V07 | P46P | P46V | P6D |

| P6P | P6S | P6V | P6W | P7D | P7P | P7S | P7V |

| P7W | P8W | PF | PF06 | PF07 | PF08 | PF09 | PV06 |

| PV07 | PV08 | PV09 | PV10 | PV15 | PV20 | PV29 | PV6 |

| R4U | R4V | R5U | R5V | T6C | T6CC | T6CR | T6D |

| T6DC | T6DCC | T6DR | T6E | T6EC | T6ED | T6ER | TMB |

| VVO1 |

Laser beam cutting

Laser beam cutting

Laser cutting uses a high powered laser to cut through sheet metal. A

series of mirrors and lenses direct and focus a high-energy beam of light onto the surface of

the sheet where it is to be cut. When the beam strikes the surface, the energy of the beam melts

and vaporizes the metal underneath. Any remaining molten metal or vapor is blown away from the

cut by a stream of gas. The position of the laser beam relative to the sheet is precisely

controlled to allow the laser to follow the desired cutting path.

This process is carried out on laser cutting machines that consist of a power supply, laser system, mirrors, focusing lens, nozzle, pressurized gas, and a workpiece table. The laser most commonly used for sheet metal cutting is a CO2 based laser with approximately 1000-2000 watts of power. However, Nd and Nd-YAG lasers are sometimes used for very high power applications. The laser beam is directed by a series of mirrors and through the "cutting head" which contains a lens and nozzle to focus the beam onto the cutting location. The beam diameter at the cutting surface is typically around 0.008 inches. In some machines, the cutting head is able to move in the X-Y plane over the workpiece which is clamped to a stationary table below. In other laser cutting machines, the cutting head remains stationary, while the table moves underneath it. Both systems allow the laser beam to cut out any 2D shape in the workpiece. As mentioned above, pressurized gas is also used in the process to blow away the molten metal and vapor as the cut is formed. This assist gas, typically oxygen or nitrogen, feeds into the cutting head and is blown out the same nozzle as the laser beam.

Laser cutting can be preformed on sheet metals that are both ferrous and non-ferrous. Materials with low reflectivity and conductivity allow the laser beam to be most effective - carbon steel, stainless steel, and titanium are most common. Metals that reflect light and conduct heat, such as aluminum and copper alloys, can still be cut but require a higher power laser. Laser cutting can also be used beyond sheet metal applications, to cut plastics, ceramics, stone, wood, etc.

As previously mentioned, laser cutting can be used to cut nearly any 2D shape. However, the most common use is cutting an external profile or complex features. Simple internal features, such as holes or slots are usually punched out using other sheet metal processes. But highly complex shapes and outer part boundaries are well suited for laser cutting. The fact that laser cutting does not require any physical contact with the material offers many benefits to the quality of the cuts. First, minimal burrs are formed, creating a smooth edge that may not require any finishing. Secondly, no tool contact means only minimal distortion of the sheet will occur. Also, only a small amount of heat distortion is present in the narrow zone affected by the laser beam. Lastly, no contaminates will be embedded into the material during cutting. Although not a quality issue, it is worth noting that the lack of physical tool wear will reduce costs and make laser cutting cost effective for low volume production.

This process is carried out on laser cutting machines that consist of a power supply, laser system, mirrors, focusing lens, nozzle, pressurized gas, and a workpiece table. The laser most commonly used for sheet metal cutting is a CO2 based laser with approximately 1000-2000 watts of power. However, Nd and Nd-YAG lasers are sometimes used for very high power applications. The laser beam is directed by a series of mirrors and through the "cutting head" which contains a lens and nozzle to focus the beam onto the cutting location. The beam diameter at the cutting surface is typically around 0.008 inches. In some machines, the cutting head is able to move in the X-Y plane over the workpiece which is clamped to a stationary table below. In other laser cutting machines, the cutting head remains stationary, while the table moves underneath it. Both systems allow the laser beam to cut out any 2D shape in the workpiece. As mentioned above, pressurized gas is also used in the process to blow away the molten metal and vapor as the cut is formed. This assist gas, typically oxygen or nitrogen, feeds into the cutting head and is blown out the same nozzle as the laser beam.

Laser cutting can be preformed on sheet metals that are both ferrous and non-ferrous. Materials with low reflectivity and conductivity allow the laser beam to be most effective - carbon steel, stainless steel, and titanium are most common. Metals that reflect light and conduct heat, such as aluminum and copper alloys, can still be cut but require a higher power laser. Laser cutting can also be used beyond sheet metal applications, to cut plastics, ceramics, stone, wood, etc.

As previously mentioned, laser cutting can be used to cut nearly any 2D shape. However, the most common use is cutting an external profile or complex features. Simple internal features, such as holes or slots are usually punched out using other sheet metal processes. But highly complex shapes and outer part boundaries are well suited for laser cutting. The fact that laser cutting does not require any physical contact with the material offers many benefits to the quality of the cuts. First, minimal burrs are formed, creating a smooth edge that may not require any finishing. Secondly, no tool contact means only minimal distortion of the sheet will occur. Also, only a small amount of heat distortion is present in the narrow zone affected by the laser beam. Lastly, no contaminates will be embedded into the material during cutting. Although not a quality issue, it is worth noting that the lack of physical tool wear will reduce costs and make laser cutting cost effective for low volume production.

Capabilities

- Sheet thickness: 0.02-0.50 in.

- Cutting speed: 30-500 IPM (1000 IPM feasible)

- Kerf width: 0.006-0.016 in. (0.004 in. feasible)

- Tolerance: ±0.005 in. (±0.001 in. feasible)

- Surface finish: 125-250 μin

Design rules

- Edges - Burrs are minimal, but can be further reduced by using a thinner sheet stock.

- Corners - Rounded corners are preferred to sharp corners. Interior corners must have a minimum radius equal to the laser beam radius.

- Holes - Minimum hole diameter should be approximately 20% of sheet thickness, down to 0.010 inches. Laser-cut holes will have a slight natural taper.

- Multiple sheets can be cut at once to reduce cost

Drill Size Chart

Drill Size Chart

The drill size chart provides a list of standard size drill bits in several measurement systems, including fractional, metric, wire gauge number, and letter. The decimal equivalents of the diameters are shown in both English and Metric units. Fractional sizes are measured in inches, while metric sizes are measured in millimeters. The wire gauge and letter systems refer to tool diameters that increase as the wire gauge decreases from #107 to #1 and then continues from A to Z. The drill size chart contains tools up to 1.5 inches in diameter, but larger tools are also commonly used.| Drill size | Diameter (in) | Diameter (mm) |

|---|---|---|

| #107 | 0.0019 | 0.0483 |

| 0.05 mm | 0.0020 | 0.0500 |

| #106 | 0.0023 | 0.0584 |

| #105 | 0.0027 | 0.0686 |

| #104 | 0.0031 | 0.0787 |

| #103 | 0.0035 | 0.0889 |

| #102 | 0.0039 | 0.0991 |

| 0.1 mm | 0.0039 | 0.1000 |

| #101 | 0.0043 | 0.1092 |

| #100 | 0.0047 | 0.1194 |

| #99 | 0.0051 | 0.1295 |

| #98 | 0.0055 | 0.1397 |

| #97 | 0.0059 | 0.1499 |

| #96 | 0.0063 | 0.1600 |

| #95 | 0.0067 | 0.1702 |

| #94 | 0.0071 | 0.1803 |

| #93 | 0.0075 | 0.1905 |

| 0.2 mm | 0.0079 | 0.2000 |

| #92 | 0.0079 | 0.2007 |

| #91 | 0.0083 | 0.2108 |

| #90 | 0.0087 | 0.2210 |

| #89 | 0.0091 | 0.2311 |

| #88 | 0.0095 | 0.2413 |

| #87 | 0.0100 | 0.2540 |

| #86 | 0.0105 | 0.2667 |

| #85 | 0.0110 | 0.2794 |

| #84 | 0.0115 | 0.2921 |

| 0.3 mm | 0.0118 | 0.3000 |

| #83 | 0.0120 | 0.3048 |

| #82 | 0.0125 | 0.3175 |

| #81 | 0.0130 | 0.3302 |

| #80 | 0.0135 | 0.3429 |

| #79 | 0.0145 | 0.3680 |

| 1/64 in | 0.0156 | 0.3969 |

| 0.4 mm | 0.0158 | 0.4000 |

| #78 | 0.0160 | 0.4064 |

| #77 | 0.0180 | 0.4572 |

| 0.5 mm | 0.0197 | 0.5000 |

| #76 | 0.0200 | 0.5080 |

| #75 | 0.0210 | 0.5334 |

| #74 | 0.0225 | 0.5715 |

| 0.6 mm | 0.0236 | 0.6000 |

| #73 | 0.0240 | 0.6096 |

| #72 | 0.0250 | 0.6350 |

| #71 | 0.0260 | 0.6604 |

| 0.7 mm | 0.0276 | 0.7000 |

| #70 | 0.0280 | 0.7112 |

| #69 | 0.0292 | 0.7417 |

| #68 | 0.0310 | 0.7874 |

| 1/32 in | 0.0313 | 0.7938 |

| 0.8 mm | 0.0315 | 0.8000 |

| #67 | 0.0320 | 0.8128 |

| #66 | 0.0330 | 0.8382 |

| #65 | 0.0350 | 0.8890 |

| 0.9 mm | 0.0354 | 0.9000 |

| #64 | 0.0360 | 0.9144 |

| #63 | 0.0370 | 0.9398 |

| #62 | 0.0380 | 0.9652 |

| #61 | 0.0390 | 0.9906 |

| 1 mm | 0.0394 | 1.0000 |

| #60 | 0.0400 | 1.0160 |

| #59 | 0.0410 | 1.0414 |

| #58 | 0.0420 | 1.0668 |

| #57 | 0.0430 | 1.0922 |

| 1.1 mm | 0.0433 | 1.1000 |

| #56 | 0.0465 | 1.1811 |

| 3/64 in | 0.0469 | 1.1906 |

| 1.2 mm | 0.0472 | 1.2000 |

| 1.3 mm | 0.0512 | 1.3000 |

| #55 | 0.0520 | 1.3208 |

| #54 | 0.0550 | 1.3970 |

| 1.4 mm | 0.0551 | 1.4000 |

| 1.5 mm | 0.0591 | 1.5000 |

| #53 | 0.0595 | 1.5113 |

| 1/16 in | 0.0625 | 1.5875 |

| 1.6 mm | 0.0630 | 1.6000 |

| #52 | 0.0635 | 1.6129 |

| 1.7 mm | 0.0669 | 1.7000 |

| #51 | 0.0670 | 1.7018 |

| #50 | 0.0700 | 1.7780 |

| 1.8 mm | 0.0709 | 1.8000 |

| #49 | 0.0730 | 1.8542 |

| 1.9 mm | 0.0748 | 1.9000 |

| #48 | 0.0760 | 1.9304 |

| 5/64 in | 0.0781 | 1.9844 |

| #47 | 0.0785 | 1.9939 |

| 2 mm | 0.0787 | 2.0000 |

| #46 | 0.0810 | 2.0574 |

| #45 | 0.0820 | 2.0828 |

| 2.1 mm | 0.0827 | 2.1000 |

| #44 | 0.0860 | 2.1844 |

| 2.2 mm | 0.0866 | 2.2000 |

| #43 | 0.0890 | 2.2606 |

| 2.3 mm | 0.0906 | 2.3000 |

| #42 | 0.0935 | 2.3749 |

| 3/32 in | 0.0938 | 2.3813 |

| 2.4 mm | 0.0945 | 2.4000 |

| #41 | 0.0960 | 2.4384 |

| #40 | 0.0980 | 2.4892 |

| 2.5 mm | 0.0984 | 2.5000 |

| #39 | 0.0995 | 2.5273 |

| #38 | 0.1015 | 2.5781 |

| 2.6 mm | 0.1024 | 2.6000 |

| #37 | 0.1040 | 2.6416 |

| 2.7 mm | 0.1063 | 2.7000 |

| #36 | 0.1065 | 2.7051 |

| 7/64 in | 0.1094 | 2.7781 |

| #35 | 0.1100 | 2.7940 |

| 2.8 mm | 0.1102 | 2.8000 |

| #34 | 0.1110 | 2.8194 |

| #33 | 0.1130 | 2.8702 |

| 2.9 mm | 0.1142 | 2.9000 |

| #32 | 0.1160 | 2.9464 |

| 3 mm | 0.1181 | 3.0000 |

| #31 | 0.1200 | 3.0480 |

| 3.1 mm | 0.1221 | 3.1000 |

| 1/8 in | 0.1250 | 3.1750 |

| 3.2 mm | 0.1260 | 3.2000 |

| #30 | 0.1285 | 3.2639 |

| 3.3 mm | 0.1299 | 3.3000 |

| 3.4 mm | 0.1339 | 3.4000 |

| #29 | 0.1360 | 3.4544 |

| 3.5 mm | 0.1378 | 3.5000 |

| #28 | 0.1405 | 3.5687 |

| 9/64 in | 0.1406 | 3.5719 |

| 3.6 mm | 0.1417 | 3.6000 |

| #27 | 0.1440 | 3.6576 |

| 3.7 mm | 0.1457 | 3.7000 |

| #26 | 0.1470 | 3.7338 |

| #25 | 0.1495 | 3.7973 |

| 3.8 mm | 0.1496 | 3.8000 |

| #24 | 0.1520 | 3.8608 |

| 3.9 mm | 0.1535 | 3.9000 |

| #23 | 0.1540 | 3.9116 |

| 5/32 in | 0.1563 | 3.9688 |

| #22 | 0.1570 | 3.9878 |

| 4 mm | 0.1575 | 4.0000 |

| #21 | 0.1590 | 4.0386 |

| #20 | 0.1610 | 4.0894 |

| 4.1 mm | 0.1614 | 4.1000 |

| 4.2 mm | 0.1654 | 4.2000 |

| #19 | 0.1660 | 4.2164 |

| 4.3 mm | 0.1693 | 4.3000 |

| #18 | 0.1695 | 4.3053 |

| 11/64 in | 0.1719 | 4.3656 |

| #17 | 0.1730 | 4.3942 |

| 4.4 mm | 0.1732 | 4.4000 |

| #16 | 0.1770 | 4.4958 |

| 4.5 mm | 0.1772 | 4.5000 |

| #15 | 0.1800 | 4.5720 |

| 4.6 mm | 0.1811 | 4.6000 |

| #14 | 0.1820 | 4.6228 |

| #13 | 0.1850 | 4.6990 |

| 4.7 mm | 0.1850 | 4.7000 |

| 3/16 in | 0.1875 | 4.7625 |

| 4.8 mm | 0.1890 | 4.8000 |

| #12 | 0.1890 | 4.8006 |

| #11 | 0.1910 | 4.8514 |

| 4.9 mm | 0.1929 | 4.9000 |

| #10 | 0.1935 | 4.9149 |

| #9 | 0.1960 | 4.9784 |

| 5 mm | 0.1969 | 5.0000 |

| #8 | 0.1990 | 5.0546 |

| 5.1 mm | 0.2008 | 5.1000 |

| #7 | 0.2010 | 5.1054 |

| 13/64 in | 0.2031 | 5.1594 |

| #6 | 0.2040 | 5.1816 |

| 5.2 mm | 0.2047 | 5.2000 |

| #5 | 0.2055 | 5.2197 |

| 5.3 mm | 0.2087 | 5.3000 |

| #4 | 0.2090 | 5.3086 |

| 5.4 mm | 0.2126 | 5.4000 |

| #3 | 0.2130 | 5.4102 |

| 5.5 mm | 0.2165 | 5.5000 |

| 7/32 in | 0.2188 | 5.5563 |

| 5.6 mm | 0.2205 | 5.6000 |

| #2 | 0.2210 | 5.6134 |

| 5.7 mm | 0.2244 | 5.7000 |

| #1 | 0.2280 | 5.7912 |

| 5.8 mm | 0.2284 | 5.8000 |

| 5.9 mm | 0.2323 | 5.9000 |

| A | 0.2340 | 5.9436 |

| 15/64 in | 0.2344 | 5.9531 |

| 6 mm | 0.2362 | 6.0000 |

| B | 0.2380 | 6.0452 |

| 6.1 mm | 0.2402 | 6.1000 |

| C | 0.2420 | 6.1468 |

| 6.2 mm | 0.2441 | 6.2000 |

| D | 0.2460 | 6.2484 |

| 6.3 mm | 0.2480 | 6.3000 |

| 1/4 in | 0.2500 | 6.3500 |

| E | 0.2500 | 6.3500 |

| 6.4 mm | 0.2520 | 6.4000 |

| 6.5 mm | 0.2559 | 6.5000 |

| F | 0.2570 | 6.5278 |

| 6.6 mm | 0.2598 | 6.6000 |

| G | 0.2610 | 6.6294 |

| 6.7 mm | 0.2638 | 6.7000 |

| 17/64 in | 0.2656 | 6.7469 |

| H | 0.2660 | 6.7564 |

| 6.8 mm | 0.2677 | 6.8000 |

| 6.9 mm | 0.2717 | 6.9000 |

| I | 0.2720 | 6.9088 |

| 7 mm | 0.2756 | 7.0000 |

| J | 0.2770 | 7.0358 |

| 7.1 mm | 0.2795 | 7.1000 |

| K | 0.2810 | 7.1374 |

| 9/32 in | 0.2813 | 7.1438 |

| 7.2 mm | 0.2835 | 7.2000 |

| 7.3 mm | 0.2874 | 7.3000 |

| L | 0.2900 | 7.3660 |

| 7.4 mm | 0.2913 | 7.4000 |

| M | 0.2950 | 7.4930 |

| 7.5 mm | 0.2953 | 7.5000 |

| 19/64 in | 0.2969 | 7.5406 |

| 7.6 mm | 0.2992 | 7.6000 |

| N | 0.3020 | 7.6708 |

| 7.7 mm | 0.3032 | 7.7000 |

| 7.8 mm | 0.3071 | 7.8000 |

| 7.9 mm | 0.3110 | 7.9000 |

| 5/16 in | 0.3125 | 7.9375 |

| 8 mm | 0.3150 | 8.0000 |

| O | 0.3160 | 8.0264 |

| 8.1 mm | 0.3189 | 8.1000 |

| 8.2 mm | 0.3228 | 8.2000 |

| P | 0.3230 | 8.2042 |

| 8.3 mm | 0.3268 | 8.3000 |

| 21/64 in | 0.3281 | 8.3344 |

| 8.4 mm | 0.3307 | 8.4000 |

| Q | 0.3320 | 8.4328 |

| 8.5 mm | 0.3347 | 8.5000 |

| 8.6 mm | 0.3386 | 8.6000 |

| R | 0.3390 | 8.6106 |

| 8.7 mm | 0.3425 | 8.7000 |

| 11/32 in | 0.3438 | 8.7313 |

| 8.8 mm | 0.3465 | 8.8000 |

| S | 0.3480 | 8.8392 |

| 8.9 mm | 0.3504 | 8.9000 |

| 9 mm | 0.3543 | 9.0000 |

| T | 0.3580 | 9.0932 |

| 9.1 mm | 0.3583 | 9.1000 |

| 23/64 in | 0.3594 | 9.1281 |

| 9.2 mm | 0.3622 | 9.2000 |

| 9.3 mm | 0.3661 | 9.3000 |

| U | 0.3680 | 9.3472 |

| 9.4 mm | 0.3701 | 9.4000 |

| 9.5 mm | 0.3740 | 9.5000 |

| 3/8 in | 0.3750 | 9.5250 |

| V | 0.3770 | 9.5758 |

| 9.6 mm | 0.3780 | 9.6000 |

| 9.7 mm | 0.3819 | 9.7000 |

| 9.8 mm | 0.3858 | 9.8000 |

| W | 0.3860 | 9.8044 |

| 9.9 mm | 0.3898 | 9.9000 |

| 25/64 in | 0.3906 | 9.9219 |

| 10 mm | 0.3937 | 10.0000 |

| X | 0.3970 | 10.0838 |

| Y | 0.4040 | 10.2616 |

| 13/32 in | 0.4063 | 10.3188 |

| Z | 0.4130 | 10.4902 |

| 10.5 mm | 0.4134 | 10.5000 |

| 27/64 in | 0.4219 | 10.7156 |

| 11 mm | 0.4331 | 11.0000 |

| 7/16 in | 0.4375 | 11.1125 |

| 11.5 mm | 0.4528 | 11.5000 |

| 29/64 in | 0.4531 | 11.5094 |

| 15/32 in | 0.4688 | 11.9063 |

| 12 mm | 0.4724 | 12.0000 |

| 31/64 in | 0.4844 | 12.3031 |

| 12.5 mm | 0.4921 | 12.5000 |

| 1/2 in | 0.5000 | 12.7000 |

| 13 mm | 0.5118 | 13.0000 |

| 33/64 in | 0.5156 | 13.0969 |

| 17/32 in | 0.5313 | 13.4938 |

| 13.5 mm | 0.5315 | 13.5000 |

| 35/64 in | 0.5469 | 13.8906 |

| 14 mm | 0.5512 | 14.0000 |

| 9/16 in | 0.5625 | 14.2875 |

| 14.5 mm | 0.5709 | 14.5000 |

| 37/64 in | 0.5781 | 14.6844 |

| 15 mm | 0.5906 | 15.0000 |

| 19/32 in | 0.5938 | 15.0813 |

| 39/64 in | 0.6094 | 15.4781 |

| 15.5 mm | 0.6102 | 15.5000 |

| 5/8 in | 0.6250 | 15.8750 |

| 16 mm | 0.6299 | 16.0000 |

| 41/64 in | 0.6406 | 16.2719 |

| 16.5 mm | 0.6496 | 16.5000 |

| 17 mm | 0.6693 | 17.0000 |

| 43/64 in | 0.6719 | 17.0656 |

| 11/16 in | 0.6875 | 17.4625 |

| 17.5 mm | 0.6890 | 17.5000 |

| 45/64 in | 0.7031 | 17.8594 |

| 18 mm | 0.7087 | 18.0000 |

| 23/32 in | 0.7188 | 18.2563 |

| 18.5 mm | 0.7284 | 18.5000 |

| 47/64 in | 0.7344 | 18.6531 |

| 19 mm | 0.7480 | 19.0000 |

| 3/4 in | 0.7500 | 19.0500 |

| 49/64 in | 0.7656 | 19.4469 |

| 19.5 mm | 0.7677 | 19.5000 |

| 25/32 in | 0.7813 | 19.8438 |

| 20 mm | 0.7874 | 20.0000 |

| 51/64 in | 0.7969 | 20.2406 |

| 20.5 mm | 0.8071 | 20.5000 |

| 13/16 in | 0.8125 | 20.6375 |

| 21 mm | 0.8268 | 21.0000 |

| 53/64 in | 0.8281 | 21.0344 |

| 27/32 in | 0.8438 | 21.4313 |

| 21.5 mm | 0.8465 | 21.5000 |

| 55/64 in | 0.8594 | 21.8281 |

| 22 mm | 0.8661 | 22.0000 |

| 7/8 in | 0.8750 | 22.2250 |

| 22.5 mm | 0.8858 | 22.5000 |

| 57/64 in | 0.8906 | 22.6219 |

| 23 mm | 0.9055 | 23.0000 |

| 29/32 in | 0.9063 | 23.0188 |

| 21/23 in | 0.9130 | 23.1913 |

| 59/64 in | 0.9219 | 23.4156 |

| 23.5 mm | 0.9252 | 23.5000 |

| 15/16 in | 0.9375 | 23.8125 |

| 24 mm | 0.9449 | 24.0000 |

| 61/64 in | 0.9531 | 24.2094 |

| 24.5 mm | 0.9646 | 24.5000 |

| 31/32 in | 0.9688 | 24.6063 |

| 25 mm | 0.9843 | 25.0000 |

| 63/64 in | 0.9844 | 25.0031 |

| 1 in | 1.0000 | 25.4000 |

| 25.5 mm | 1.0039 | 25.5000 |

| 1 1/64 in | 1.0156 | 25.7969 |

| 26 mm | 1.0236 | 26.0000 |

| 1 1/32 in | 1.0313 | 26.1938 |

| 26.5 mm | 1.0433 | 26.5000 |

| 1 3/64 in | 1.0469 | 26.5906 |

| 1 1/16 in | 1.0625 | 26.9875 |

| 27 mm | 1.0630 | 27.0000 |

| 1 5/64 in | 1.0781 | 27.3844 |

| 27.5 mm | 1.0827 | 27.5000 |

| 1 3/32 in | 1.0938 | 27.7813 |

| 28 mm | 1.1024 | 28.0000 |

| 1 7/64 in | 1.1094 | 28.1781 |

| 28.5 mm | 1.1221 | 28.5000 |

| 1 1/8 in | 1.1250 | 28.5750 |

| 1 9/64 in | 1.1406 | 28.9719 |

| 29 mm | 1.1417 | 29.0000 |

| 1 5/32 in | 1.1563 | 29.3688 |

| 29.5 mm | 1.1614 | 29.5000 |

| 1 11/64 in | 1.1719 | 29.7656 |

| 30 mm | 1.1811 | 30.0000 |

| 1 3/16 in | 1.1875 | 30.1625 |

| 30.5 mm | 1.2008 | 30.5000 |

| 1 13/64 in | 1.2031 | 30.5594 |

| 1 7/32 in | 1.2188 | 30.9563 |

| 31 mm | 1.2205 | 31.0000 |

| 1 15/64 in | 1.2344 | 31.3531 |

| 31.5 mm | 1.2402 | 31.5000 |

| 1 1/4 in | 1.2500 | 31.7500 |

| 32 mm | 1.2598 | 32.0000 |

| 1 17/64 in | 1.2656 | 32.1469 |

| 32.5 mm | 1.2795 | 32.5000 |

| 1 9/32 in | 1.2813 | 32.5438 |

| 1 19/64 in | 1.2969 | 32.9406 |

| 33 mm | 1.2992 | 33.0000 |

| 1 5/16 in | 1.3125 | 33.3375 |

| 33.5 mm | 1.3189 | 33.5000 |

| 1 21/64 in | 1.3281 | 33.7344 |

| 34 mm | 1.3386 | 34.0000 |

| 1 11/32 in | 1.3438 | 34.1313 |

| 34.5 mm | 1.3583 | 34.5000 |

| 1 23/64 in | 1.3594 | 34.5281 |

| 1 3/8 in | 1.3750 | 34.9250 |

| 35 mm | 1.3780 | 35.0000 |

| 1 25/64 in | 1.3906 | 35.3219 |

| 35.5 mm | 1.3976 | 35.5000 |

| 1 13/32 in | 1.4063 | 35.7188 |

| 36 mm | 1.4173 | 36.0000 |

| 1 27/64 in | 1.4219 | 36.1156 |

| 36.5 mm | 1.4370 | 36.5000 |

| 1 7/16 in | 1.4375 | 36.5125 |

| 1 29/64 in | 1.4531 | 36.9094 |

| 37 mm | 1.4567 | 37.0000 |

| 1 15/32 in | 1.4688 | 37.3063 |

| 37.5 mm | 1.4764 | 37.5000 |

| 1 31/64 in | 1.4844 | 37.7031 |

| 38 mm | 1.4961 | 38.0000 |

| 1 1/2 in | 1.5000 | 38.1000 |

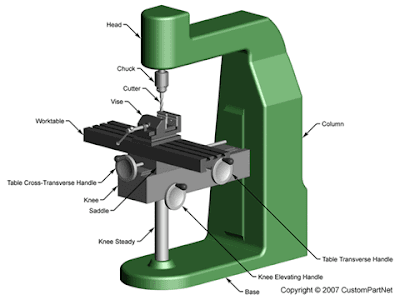

Manual vertical milling machine

Manual vertical mailling mchine

The above components of the milling machine can be oriented either vertically or horizontally, creating two very distinct forms of milling machine. A horizontal milling machine uses a cutter that is mounted on a horizontal shaft, called an arbor, above the workpiece. For this reason, horizontal milling is sometimes referred to as arbor milling. The arbor is supported on one side by an overarm, which is connected to the column, and on the other side by the spindle. The spindle is driven by a motor and therefore rotates the arbor. During milling, the cutter rotates along a horizontal axis and the side of the cutter removes material from the workpiece. A vertical milling machine, on the other hand, orients the cutter vertically. The cutter is secured inside a piece called a collet, which is then attached to the vertically oriented spindle. The spindle is located inside the milling head, which is attached to the column. The milling operations performed on a vertical milling machine remove material by using both the bottom and sides of the cutter.

Milling machines can also be classified by the type of control that is used. A manual milling machine requires the operator to control the motion of the cutter during the milling operation. The operator adjusts the position of the cutter by using hand cranks that move the table, saddle, and knee. Milling machines are also able to be computer controlled, in which case they are referred to as a computer numerical control (CNC) milling machine. CNC milling machines move the workpiece and cutter based on commands that are preprogrammed and offer very high precision. The programs that are written are often called G-codes or NC-codes. Many CNC milling machines also contain another axis of motion besides the standard X-Y-Z motion. The angle of the spindle and cutter can be changed, allowing for even more complex shapes to be milled.

|

| Manual vertical milling machine |

Standard Manufacturing Chart Thickness's

Standard Manufacturing Chart Thickness's

Gauge (or gage) sizes are numbers that indicate the thickness of a piece of sheet metal, with a higher number referring to a thinner sheet. The equivalent thicknesses differ for each gauge size standard, which were developed based on the weight of the sheet for a given material. The Manufacturers' Standard Gage provides the thicknesses for standard steel, galvanized steel, and stainless steel. The Brown and Sharpe Gage, also known as the American Wire Gage (AWG), is used for most non ferrous metals, such as Aluminum and Brass. In the UK, the Birmingham Gage (BG) is used for a variety of metals and should not be confused with the Birmingham Wire Gage (BWG), which is used for wires. Lastly, a standard exists for Zinc in which a higher gauge number indicates a thicker sheet. The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.

| Thickness | ||||

|---|---|---|---|---|

| Weight Per Area | ||||

| Gauge | in | mm | lb/ft² | kg/m² |

| 3 | 0.2391 | 6.073 | 9.754 | 47.624 |

| 4 | 0.2242 | 5.695 | 9.146 | 44.656 |

| 5 | 0.2092 | 5.314 | 8.534 | 41.668 |

| 6 | 0.1943 | 4.935 | 7.927 | 38.701 |

| 7 | 0.1793 | 4.554 | 7.315 | 35.713 |

| 8 | 0.1644 | 4.176 | 6.707 | 32.745 |

| 9 | 0.1495 | 3.797 | 6.099 | 29.777 |

| 10 | 0.1345 | 3.416 | 5.487 | 26.790 |

| 11 | 0.1196 | 3.038 | 4.879 | 23.822 |

| 12 | 0.1046 | 2.657 | 4.267 | 20.834 |

| 13 | 0.0897 | 2.278 | 3.659 | 17.866 |

| 14 | 0.0747 | 1.897 | 3.047 | 14.879 |

| 15 | 0.0673 | 1.709 | 2.746 | 13.405 |

| 16 | 0.0598 | 1.519 | 2.440 | 11.911 |

| 17 | 0.0538 | 1.367 | 2.195 | 10.716 |

| 18 | 0.0478 | 1.214 | 1.950 | 9.521 |

| 19 | 0.0418 | 1.062 | 1.705 | 8.326 |

| 20 | 0.0359 | 0.912 | 1.465 | 7.151 |

| 21 | 0.0329 | 0.836 | 1.342 | 6.553 |

| 22 | 0.0299 | 0.759 | 1.220 | 5.955 |

| 23 | 0.0269 | 0.683 | 1.097 | 5.358 |

| 24 | 0.0239 | 0.607 | 0.975 | 4.760 |

| 25 | 0.0209 | 0.531 | 0.853 | 4.163 |

| 26 | 0.0179 | 0.455 | 0.730 | 3.565 |

| 27 | 0.0164 | 0.417 | 0.669 | 3.267 |

| 28 | 0.0149 | 0.378 | 0.608 | 2.968 |

| 29 | 0.0135 | 0.343 | 0.551 | 2.689 |

| 30 | 0.0120 | 0.305 | 0.490 | 2.390 |

| 31 | 0.0105 | 0.267 | 0.428 | 2.091 |

| 32 | 0.0097 | 0.246 | 0.396 | 1.932 |

| 33 | 0.0090 | 0.229 | 0.367 | 1.793 |

| 34 | 0.0082 | 0.208 | 0.335 | 1.633 |

| 35 | 0.0075 | 0.191 | 0.306 | 1.494 |

| 36 | 0.0067 | 0.170 | 0.273 | 1.335 |

| 37 | 0.0064 | 0.163 | 0.261 | 1.275 |

| 38 | 0.0060 | 0.152 | 0.245 | 1.195 |

Sheet Metal Table

Gauge size standard:

| Thickness | Weight Per Area | |||

|---|---|---|---|---|

| Gauge | in | mm | lb/ft² | kg/m² |

| 000000 | 0.5800 | 14.732 | 8.185 | 39.962 |

| 00000 | 0.5165 | 13.119 | 7.289 | 35.587 |

| 0000 | 0.4600 | 11.684 | 6.492 | 31.694 |

| 000 | 0.4096 | 10.404 | 5.780 | 28.222 |

| 00 | 0.3648 | 9.266 | 5.148 | 25.135 |

| 0 | 0.3249 | 8.252 | 4.585 | 22.386 |

| 1 | 0.2893 | 7.348 | 4.083 | 19.933 |

| 2 | 0.2576 | 6.543 | 3.635 | 17.749 |

| 3 | 0.2294 | 5.827 | 3.237 | 15.806 |

| 4 | 0.2043 | 5.189 | 2.883 | 14.076 |

| 5 | 0.1819 | 4.620 | 2.567 | 12.533 |

| 6 | 0.1620 | 4.115 | 2.286 | 11.162 |

| 7 | 0.1443 | 3.665 | 2.036 | 9.942 |

| 8 | 0.1285 | 3.264 | 1.813 | 8.854 |

| 9 | 0.1144 | 2.906 | 1.614 | 7.882 |

| 10 | 0.1019 | 2.588 | 1.438 | 7.021 |

| 11 | 0.0907 | 2.304 | 1.280 | 6.249 |

| 12 | 0.0808 | 2.052 | 1.140 | 5.567 |

| 13 | 0.0720 | 1.829 | 1.016 | 4.961 |

| 14 | 0.0641 | 1.628 | 0.905 | 4.417 |

| 15 | 0.0571 | 1.450 | 0.806 | 3.934 |

| 16 | 0.0508 | 1.290 | 0.717 | 3.500 |

| 17 | 0.0453 | 1.151 | 0.639 | 3.121 |

| 18 | 0.0403 | 1.024 | 0.569 | 2.777 |

| 19 | 0.0359 | 0.912 | 0.507 | 2.474 |

| 20 | 0.0320 | 0.813 | 0.452 | 2.205 |

| 21 | 0.0285 | 0.724 | 0.402 | 1.964 |

| 22 | 0.0253 | 0.643 | 0.357 | 1.743 |

| 23 | 0.0226 | 0.574 | 0.319 | 1.557 |

| 24 | 0.0201 | 0.511 | 0.284 | 1.385 |

| 25 | 0.0179 | 0.455 | 0.253 | 1.233 |

| 26 | 0.0159 | 0.404 | 0.224 | 1.096 |

| 27 | 0.0142 | 0.361 | 0.200 | 0.978 |

| 28 | 0.0126 | 0.320 | 0.178 | 0.868 |

| 29 | 0.0113 | 0.287 | 0.159 | 0.779 |

| 30 | 0.0100 | 0.254 | 0.141 | 0.689 |

| 31 | 0.0089 | 0.226 | 0.126 | 0.613 |

| 32 | 0.0080 | 0.203 | 0.113 | 0.551 |

| 33 | 0.0071 | 0.180 | 0.100 | 0.489 |

| 34 | 0.0063 | 0.160 | 0.089 | 0.434 |

| 35 | 0.0056 | 0.142 | 0.079 | 0.386 |

| 36 | 0.0050 | 0.127 | 0.071 | 0.345 |

| 37 | 0.0045 | 0.114 | 0.064 | 0.310 |

| 38 | 0.0040 | 0.102 | 0.056 | 0.276 |

| 39 | 0.0035 | 0.089 | 0.049 | 0.241 |

| 40 | 0.0031 | 0.079 | 0.044 | 0.214 |

Subscribe to:

Comments (Atom)